About Us

The TC Composites Story

At the core of TC Composites lies a very experienced team with over 30 years of collective experience in the manufacturing and automotive industries, wielding previous experience in the Formula 1 arena.

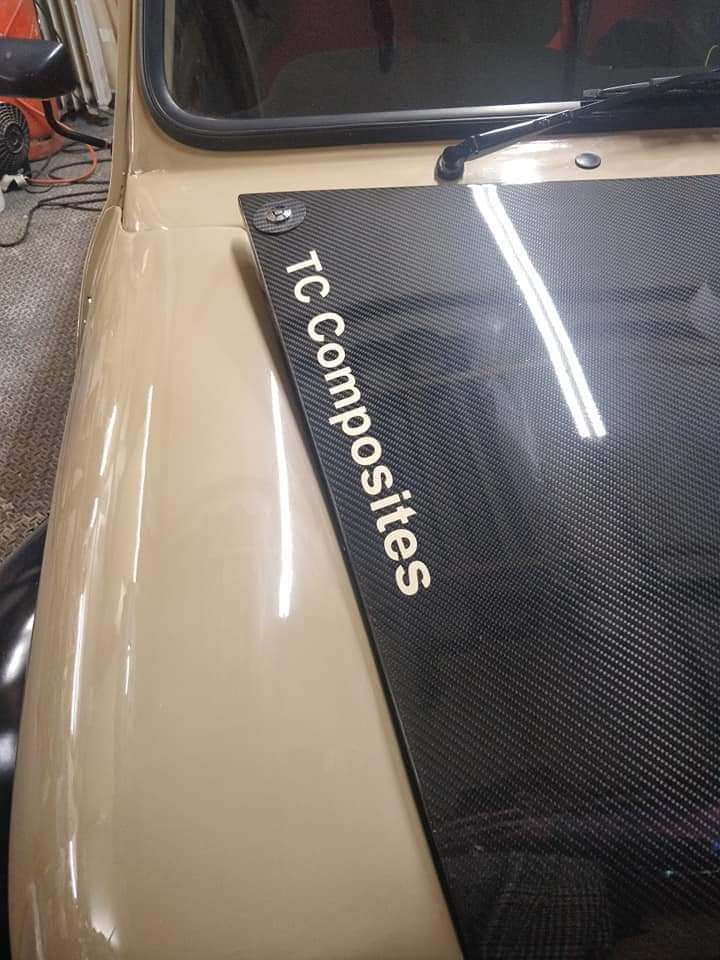

With an extensive mechanical and engineering background, coupled with a love for all things cars (especially Minis), it made perfect sense to amalgamate these interests and adopt the latest technologies to begin creating carbon fibre car parts, giving these cars a fresh modern appearance whilst benefiting from the immense weight savings. [When you only have 62 horsepower to begin with, this helps considerably!]

It was only a matter of time once friends, family and the local car communities had seen these little Minis adorned with shiny and beautifully crafted carbon fibre pieces, that they were all requesting parts to be made for their own cars. Having previously started in a shed at the bottom of the garden, it was time to scale up – This led to the birth of TC Composites as we know it today.

With a keen interest in developing and using the latest technologies and methods, TC Composites honed its production processes over the years, now creating all products from the highest quality ‘pre-preg’ carbon fibre. See more about the manufacturing process in the Why are TC Composites’ Products The Best section.

TC Composites has enjoyed accelerated growth due to the success of its classic Mini carbon fibre parts, and now offers a range of products covering the BMW Mini lineup also.

No part is too complex nor challenging – Should you have a requirement or an idea for a part in carbon fibre that is not currently produced, just contact us for a bespoke quote. This can also be a non-car part.

Why are TC Composites products the best?

All TC Composites products are meticulously designed and produced from the highest grade pre-preg carbon fibre. TC believes that the highest quality raw materials will result in the best end products for its customers.

Products are oven-cured whilst under vacuum, for improved temperature stability throughout the curing process. The temperatures are moderated and monitored throughout using computer controlled equipment. An ultra-violet protective 2K automotive lacquer is then used to protect your carbon fibre part and give it a high gloss finish, not only showing off the impressive carbon weave beneath but ensuring a long life whilst being sure to make your vehicle stand out amongst the crowd.

What is pre-preg, you may ask?

Pre-preg is a composite material made from “pre-impregnated” fibres and a partially cured polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins.

Customisation

TC Composites work closely with their customers to create the perfect product to suit their needs.

Customisations available include, but are not limited to:

- Different lacquer finishes

- Fixtures and fittings pre-drilled upon request

- Fully bespoke product requests